As CO2 gains more traction in our industry, our customers will ask what the advantages of CO2 are over ammonia and synthetic refrigerants. I feel this article (while it drills into the thermophysical properties quite a bit) helps clarify the advantages and disadvantages of one of the re-emerging refrigerants in our industry, CO2. Please contact Carlson & Stewart Refrigeration (https://carlsonstewart.com/) with any questions you have regarding all your refrigeration needs!

Source: https://instrumentationtools.com/co2-refrigerant/

Author Credit: Jane Yu

Author’s References:

• Danfoss 2019, “Three Danfoss technologies named winners of 2020 AHR Expo Innovation Awards”, Danfoss, viewed 15 February 2021.

• EESI 2018, “Timeline of Major UN Climate Negotiations”, Environmental and Energy Study Institute, viewed 15 February 2021.

• Nations Climate Change 2020, “Glasgow Climate Change Conference”, The United Nations Framework Convention on Climate Change, viewed 8 February 2021.

Why is CO2 the Most Promising Refrigerant in Cooling Industry?

As a natural working medium, CO2 is a key research orientation of CFCs (Chorofluoro carbons).

In this article, we will clarify the basics about CO2 refrigeration compressors, the differences between a CO2 compressor and other types of compressors, and the advantages of CO2 as a refrigerant.

Cooling Refrigerant vs. Environmental Protection

Due to the negative impacts of chlorofluorocarbons (CFCs) on our atmosphere, environment protection and research of refrigerants to replace CFCS have become a global concern.

To address this concern, the international community has been making laborious efforts for decades.

1985: Vienna Convention for the Protection of the Ozone Layer was signed.

1987: Montreal Protocol was established.

1990: London Conference about Ozone Layer was held.

1992: The Copenhagen Amendment was made to Montreal Protocol.

1994: United Nations Framework Convention on Climate Change (UNFCCC)

1997: Under Kyoto Protocol, 37 industrialized countries agreed on the first commitment period and their targets of greenhouse gas emissions.

2007: Bali Action Plan was launched.

2011: Durban Platform for Enhanced Action (ADP)

2015: International Climate Change Conferences in Rio, Copenhagen and Paris.

2016: Paris Agreement entered into force.

2021: Glasgow Climate Change Conference rescheduled to November due to COVID-19.

Since 1994, after the United Nations Framework Convention on Climate Change (UNFCCC) was adopted, there was a Conference of Parties (COP) every year in different cities across the world.

As we can clearly see from the timeline, the process of CFCs replacement is accelerating all over the world. Phasing out of ODSs (Ozone Depleting Substances) has become an international responsibility.

The alternative working medium should meet three requirements: safety, environmental acceptability and device applicability. With years of unremitting efforts, scientists have developed a large number of transitional or long-term substitutes for chlorofluoro carbons (CFCs) and hydrochlorofluorocarbons (HCFCs), such as R134a, R407C, R410A and R290.

Relevant technologies and equipment are also under study. Some of them have been widely used in refrigeration and HVAC (Heating, Ventilating and Air Conditioning) industry already.

The Montreal Protocol compulsively requires countries in the world to phase out CFCs, HCFCs and other substances that deplete the ozone layer within a time limit, and stipulates the use period of these substances for developed and developing countries respectively. The HCFC refrigerants widely used in industry right now are listed in the greenhouse gases by Kyoto Protocol because of their obvious greenhouse effect.

Part of European countries have banned the use of HCFCs in areas of refrigeration and HVAC. Meanwhile, they further propose to phase out HCFCs from other areas.

The legislation of some countries strictly restrict or require to phase out the use of R134a refrigerant in the 2020s, which in fact makes a true dilemma for the refrigeration and HVAC industry – they need to adapt to the elimination of CFCs and HCFCs refrigerants to use HCFCs refrigerants and at the same time find the alternatives for HCFCs.

In the research of environmental protection and refrigerant substitute, natural refrigerants such as water, ammonia, hydrocarbons and CO2 are the focuses of research orientation.

G. Lorentzen of Norway, former chairman of the international refrigeration society, believes that natural refrigerants are the ultimate solution to environmental problems.

Why Use CO2 as Refrigerant?

As a natural refrigerant, CO2 has many advantages over other substances.

Here is the PRO list.

• Low kinematic viscosity

• Low dynamic viscosity

• Small pressure ratio (about 2.5 ~ 3.0)

• Small volume

• Large refrigerating capacity per unit volume

• High thermal conductivity

• High heat capacity at constant pressure

• Low surface tension

• Environment protective

• Easy to buy

• Physical stability and safety

Due to its preferable performance in heating and cooling, CO2 has become a hot research topic worldwide.

Gustav Lorentzen, former chairman of the science and Technology Council of the international refrigeration society, had the opinion that CO2 was “an irreplaceable refrigerant”.

It is one of the most promising natural refrigerants and is expected to become one of the ideal environmental protection natural refrigerants in the 21st century. Therefore, various countries in the world have carried out extensive researches on refrigeration systems using CO2 as the refrigerant, and have achieved fruitful results.

At present, CO2 refrigeration technology is primarily applied in the following three areas: automobile air conditioning, heat pumps, and multi-stage refrigeration system.

Since CO2 was put forward again as an environmentally friendly refrigerant, CO2 compressors have been designed and manufactured for different uses.

There are six types of CO2 compressors now.

• Piston Compressor

• Rolling Piston Compressor

• Swing Piston Compressor

• Scroll Compressor

• Vane Compressor

• Screw Compressor

Compared with compressors of other refrigerants, CO2 compressor is characterized by high working pressure, small structure size, small pressure ratio, large pressure difference of suction and exhaust, high cooling and heating efficiency.

Manufacturers’ Innovations in CO2 Compressors

At present, more and more enterprises and manufacturers have joined in the trend to research and develop CO2 refrigeration compressors.

Big manufacturers around the world such as Danfoss, Bitzer, Dorin, and Emerson not only have launched carbon dioxide compressors one after another but also are providing carbon dioxide solutions for different commercial sectors.

Danfoss

Danfoss carbon dioxide gas cooler solution has the advantages of easy installation, simple debugging and maximum system operation efficiency.

As a positive responder to reduce carbon emissions, Danfoss CO₂ Adaptive Liquid Management Solution has won the 2020 AHR Expo Innovation Award.

Bitzer

As the first manufacturer to produce carbon dioxide refrigeration compressor, Bitzer has been keeping close contact with major customers in the world for many years.

Together with its clients, the company has been jointly researching and developing carbon dioxide refrigeration technology.

At present, the earliest carbon dioxide unit developed by Bitzer and its customers has been operating safely for nearly 20 years.

Dorin

Dorin is the manufacturer of the world’s first semi-hermetic reciprocating compressor (piston compressor) of CO2 refrigerant, which can be used in HPWH and light, medium-sized commercial refrigeration equipment.

Compressor motors with power ranging from 0.75KW to 15kw can operate in medium and high speed modes (1450 rpm and 2900 rpm). The diameter of the compressor are between 18mm and 34mm.

Emerson

As the world’s leading provider of heating, ventilating and air conditioning (HVAC) and refrigeration solutions.

Emerson’s subsidiary brand Copeland scroll compressor can be used in the low-temperature multi-stage refrigeration system, which is the only compressor in the US that meets the UL requirements for a multi-stage system of high-pressure subcritical carbon dioxide.

CO2 Scroll Compressor

In this part, we will give you a brief introduction of a specific type of CO2 compressor, the CO2 scroll compressor.

Features of CO2 Scroll Compressor

High Efficiency

The process of suction, compression and discharge of scroll compressor is continuous and unidirectional, so the harmful overheating of suction gas is small and the pressure difference between two adjacent chambers is low, thus it helps to avoid gas leakage.

As there’s no clearance volume in a scroll compressor, it leaves no expansion process that causes the decline of gas transmission coefficient. As a result, the volumetric efficiency is high and it usually can be higher than 95%.

Minimum Vibration and Noise

During the suction procedure of a scroll compressor, the compression and exhaust is continuous at the same time.

The pressure rises slowly, so the torque change is relatively small, naturally there is little vibration and noise.

The torque of the scroll-type compressor is only 1/10 of that of the rotary compressor and reciprocating compressor.

Simple Structure and Small Volume

The ratio of the number of parts of CO2 scroll compressor to that of rotor compressor and reciprocating compressor is 1:3:7, making the size of scroll compressor 40% smaller compared with reciprocating compressor, and the weight 15% lighter.

Since it has no suction and exhaust valves, less vulnerable parts, and is with a flexible mechanism with adjustable axial and radial clearance, a scroll compressor can avoid various damages caused by the possible liquid strike.

In terms of structure, the scroll refrigeration compressor can maintain high efficiency and high reliability even under high speed operation, and its maximum performance can be 13000 r/min.

Easy Discharge of Pressure

Due to the screw compressor adopts a gas support mechanism, it allows liquid compression.

Once the pressure in the compression chamber is too high, the end faces of the moving plate and the static plate can be separated, and the pressure can be released immediately.

High Gas Transmission Coefficient

The inner cavity of the compressor case is an exhaust chamber, which can reduce the preheating of suction and improve the gas transmission coefficient of the compressor.

Tight Sealing

The manufacturing accuracy of scroll compressor body line is very strict, with special precision machining equipment required.

The sealing requirement for a scroll compressor is high as well, and the sealing structure is complex.

Wide Application Scenarios

The cooling capacity of scroll compressor is between 0.75 and 15kw (excluding special models), and most of them are between 3 ~ 5kW.

Most models can be used for small household air conditioning and commercial air conditioning system. Nevertheless, the scroll compressor is not suitable for refrigeration conditions of – 5 ℃.

Comparison of CO2 Scroll Compressor with Other Types of Compressors

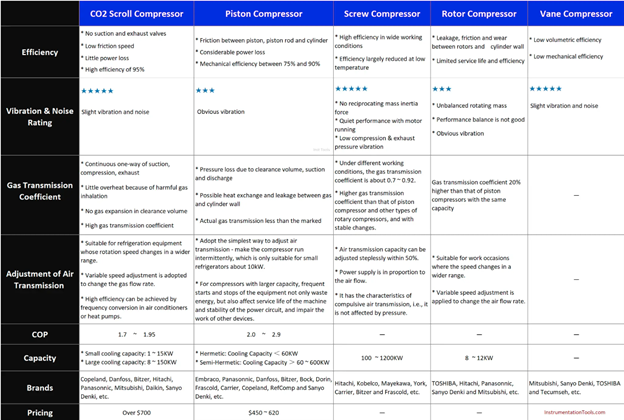

We have compared the CO2 scroll compressor with other types of compressors in the table below.

Table 1: Performance comparison of different types of compressors.

Note: Due to limited information, the symbol “—” indicates that we couldn’t find the data.

We can see that CO2 scroll refrigeration compressor is playing an irreplaceable role among other types of compressors.

In view of its features of low vibration, low noise, long life, good reliability, and high efficiency, the CO2 scroll compressor is promising to occupy a large share in the market of small and medium cooling capacity compressors.

Thus we believe since the scroll compressor is more conducive to improve the efficiency of the refrigeration system, its development prospect is brighter than any other type.

Everyone knows that for a complete refrigeration system, it can not work with only a compressor and other mechanical components. Refrigerants, or cooling medium, plays an vital role too.

Refrigerant is the working medium in refrigeration equipment. It circulates in the refrigeration system, and by the change of its own thermodynamic state, refrigerant can complete the work of energy conversion and transfer with the outside environment, so as to achieve the purpose of refrigeration.

In the later part of this article, we will see to the advantages of carbon dioxide as a refrigerant.

Properties of CO2 Refrigerant

CO2 refrigerant (R744) is a kind of natural working medium, which is colorless and tasteless at normal atmospheric temperature.

The critical temperature and pressure are 31.1 ℃ and 7.37 MPa respectively.

Pros of CO2 Refrigerant

As a refrigerant, CO2 has the following three advantages over other refrigerants.

First, regarding environment protection, the ODP of C02 is 0 and GWP is 1, which is far less than that of the refrigerants CFCs and HCFCs.

Since most of the CO2 we can use for refrigeration is chemical and industrial by-product emitted from factories, using CO2 as refrigerant is like to recycle or delay the emission of this exhaust gas, which is quite beneficial to the environment. Accordingly, C02 is an environmentally friendly working medium.

Secondly, if we see from the thermophysical properties of working medium, CO2 is perfectly suitable for refrigeration cycle and equipment.

PROS of the physical properties of CO2 are as follows:

• The evaporation latent heat of CO2 is large and the refrigerating capacity per unit volume is high (22.6 MJ / m3 at 0 ℃), about 5-8 times of that of traditional refrigerants.

• The kinematic viscosity of CO2 is very low and can be still low at low temperature.

• The thermal conductivity of CO2 is high, and the ratio of liquid density to vapor density is low. After throttling, the refrigerant can be distributed evenly in the refrigeration pipes. These excellent flow and heat transfer performances of CO2 can significantly reduce the size of compressor and refrigeration equipment, making the whole system very compact.

Thirdly, the chemical properties of CO2 are stable. It’s non-toxic, harmless, non-noncombustible, and will not decompose into toxic gases at high temperatures. Moreover, CO2 is cheap, easy to obtain, and are pretty economical.

Hazards of CO2 Refrigerant

The disadvantages of CO2 as a refrigerant are its low critical temperature (31.1 ℃) and high critical pressure (7.37 MPa).

Especially for the latter, if a trans-critical cycle is adopted in a refrigeration system, the maximum working pressure of CO2 will be10 MPa, which requires higher standards for the design of refrigeration systems and components.

Comparison of CO2 with Other Refrigerants

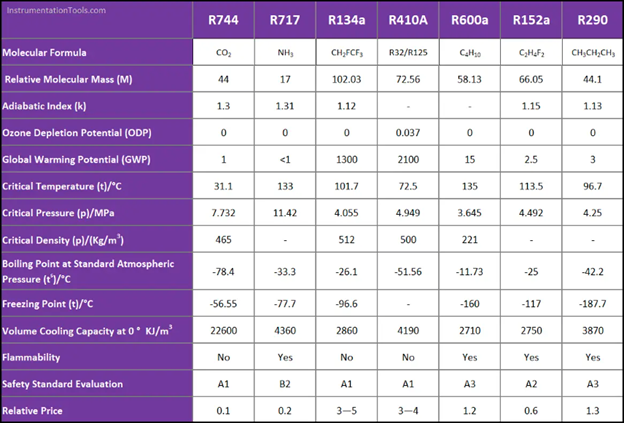

For the convenience of understanding CO2 refrigerants better, we can compare them with other refrigerants. Check Table 2 for specific data.

Table 2. Comparison of CO2 with other types of refrigerants.

Notes:

* Due to limited materials, symbol “-” in the table indicates that we couldn’t find the data.

* The relative price is relative to R12. We assume the price of R12 to be 1.

Summary

Energy saving, environment protection and low carbon life are the development direction of modern technologies. As a natural working medium, CO2 has been widely used because of its advantages of environment friendliness, non-toxicity and easy access source.

According to Table 2, we can conclude that, firstly, compared with common refrigerants, the refrigerating capacity per unit volume of CO2 refrigerant is 5.2 times that of NH3, and 7.9 times that of R134a at 0-10 ℃, 4 times of R410A, 8.4 times of R600a, 8.2 times of R152a and 5.8 times of R290.

Secondly, from the perspective of thermodynamics, CO2 is in the state of supercritical fluid, with high specific heat, high thermal conductivity and low kinematic viscosity, which makes it have better transmission performance and heat transfer characteristics and higher heat transfer efficiency than liquid and other gases.

Thirdly, compared with other refrigerants, the adiabatic index of CO2 is higher, the compression ratio of trans-critical refrigeration cycle is smaller (about 2-4), and the compression process is closer to an isentropic process. All these factors help to improve the indication efficiency of refrigeration.

Fourthly, from the perspective of environment protection, except for CO2 and NH3, other refrigerants have higher GWP (Global Warming Potential).

The GWP index of R410A is 2100 times of CO2, and R134a is 1300 times of CO2. Both of them can be put in the category of greenhouse gas that needs to be reduced. As a result, refrigerants like R410A and R134a can only be used as an alternative working medium and should not be used for a long time.

As a natural gas in the earth’s biosphere, CO2 has the lowest ODP (Ozone Depletion Potential) and GWP (Global Warming Potential), which are respectively 0 and 1.

Finally, considering from usage safety, CO2 is non-toxic, non flammable as a natural working fluid, making it a very safe substance. On the contrary, NH3, R600a, R152a, and R290 are all combustible, thus much more dangerous than CO2. By now, the industry hasn’t solved the safety problems caused by these four refrigerants yet.

To sum up, CO2 refrigerant has better properties than other refrigerants, and it is gradually used in refrigeration compressors. Though strictly speaking, CO2 is not perfect either. With its low critical temperature (31.1 ℃) and high critical pressure (7.37 MPa), the requirements for compressors and pipelines are particularly high, which will sure to increase the costs of product manufacturing.

Nevertheless, the optimistic side is that world’s top compressor manufacturers are studying improvement methods, such as the use of trans-critical circulation system. We believe that the development prospect of CO2 refrigerant is bright, and it will play a leading role in the refrigeration compressor market in the future. Many people in the industry believe this too.

As a part of natural refrigerants, there’s a promising future and market for CO2 refrigerant under our special historical period when voices of environmental protection are rising.